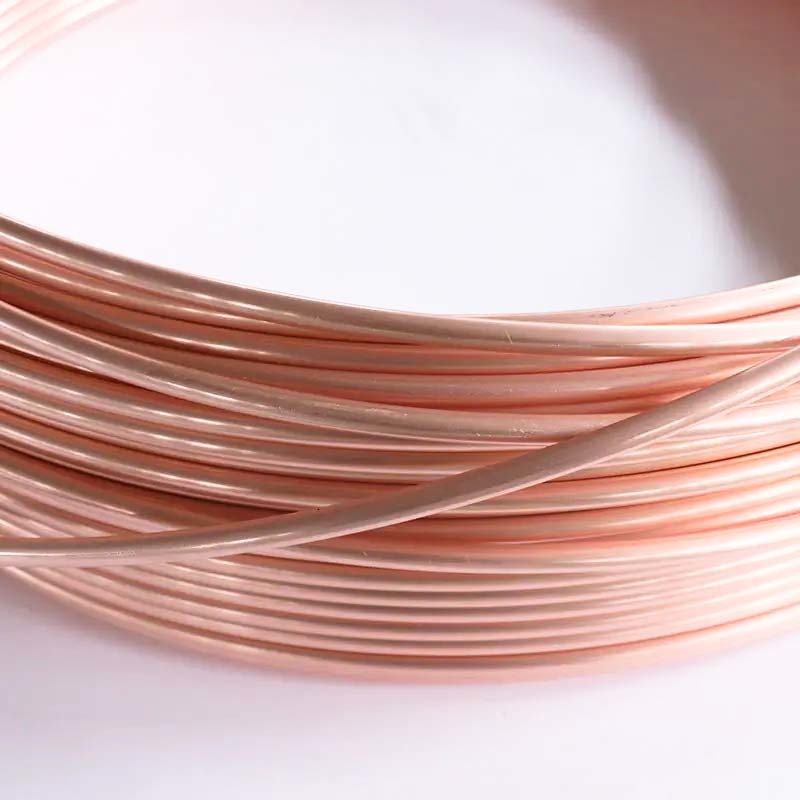

Product Description

C11000/T2 is pure copper, also known as copper, copper has good electrical conductivity, thermal conductivity, corrosion resistance and processing performance, can be welded and brazed. Contains less impurities to reduce electrical conductivity, thermal conductivity, trace oxygen has little effect on electrical conductivity, thermal conductivity and processing properties, but it is easy to cause "hydrogen disease". It is not suitable for processing (annealing, welding, etc.) and use in a reducing atmosphere at high temperature (such as> 370 ℃).

Product Parameters

|

Thickness: |

0.1-300mm,or customized |

Length: |

100-12000mm,or customized |

|

Width: |

10-3000mm,or customized |

Standard: |

ASTM,AISI,JIS,GB, DIN,EN |

|

Brand |

C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920,C10930, C11000,C11300,C11400,C11500,C11600,C12000,C12200,C12300,C12500,C14200, C14420,C14500,C14510,C14520,C14530,C17200,C19200,C21000,C23000,C26000, C27000,C27400,C28000,C33000,C33200,C37000,C44300,C44400,C44500,C60800, C63020,C65500,C68700,C70400, C70620,C71000,C71500,C71520,C71640,C72200, T1,T2,T3,TU1,TU0,TU2,TP1,TP2,TAg0.1,ect. |

||

|

Surface: |

Grinding, polishing, brightening, oiling, hair thread, brush, mirror, sandblasting or processing as required |

||

|

Certification: |

ISO.SGS.BV

|

Payment Method: |

FOB,CRF,CIF,EXW Acceptable |

|

Port of Loading: |

Any port in China |

Delivery time: |

received.30%After deposit7-15working day |

chemical composition

|

Copper+Silver With Ag: |

Tin Sn: |

Zinc Zn: |

Lead Pb: |

Nickel It is: |

Iron Fe: |

|

≥ 99.90 |

≤ 0.002 |

≤ 0.005 |

≤ 0.005 |

≤ 0.005 |

≤ 0.005 |

|

Antimony Sb: |

Sulphur S: |

Arsenic As: |

Bismuth Bi: |

Oxygen O: |

Impurity: |

|

≤ 0.002 |

≤ 0.005 |

≤ 0.002 |

≤0.001 |

≤ 0.06 |

≤0.1 |

Mechanical properties

|

Tensile Strength Kb (MPa): |

Elongation D10 (%): |

Elongation D5 (%): |

|

≥ 275 |

≥ 5 |

≥10 |

Scope of application

|

|

|

Power industry: |

|

|

Electronic industry: |

Electric vacuum devices such as high-frequency and ultra-high-frequency emission tubes, catheters, magnetrons, etc., they need high-purity oxygen-free copper and dispersion-strengthened oxygen-free copper. Copper printed circuits require a large amount of copper foil and copper-based brazing material. Integrationin the circuit Copper replaces aluminum in silicon chips for interconnect lines and lead frames. |

|

Energy and petrochemical industry: |

The main condenser tube plate and condenser tube of the energy industry thermal power plant are made of brass, bronze or cupronickel. Solar heaters are also often manufactured using copper tubing. Petrochemical industry copper and many copper alloys, used in large quantities to manufacture contact corrosion Various media containers, piping systems, filters, pumps and valves, various evaporators, heat exchangers and condensers, etc. |

|

Transportation Industry: |

In the shipbuilding industry, copper alloys include aluminum bronze, manganese bronze, aluminum brass, gunmetal (tin zinc bronze), white copper and nickel copper alloy (Monel alloy), etc. are all standard materials for shipbuilding. In warships and merchant ships, copper and copper alloys are generally used as aluminum bronze propeller, Bolts, condenser tubes, rivets, copper coated paint, etc. In the automotive industry, copper and copper alloys are mainly used in radiators, brake system pipelines, hydraulic devices, gears, bearings, power distribution and power systems, brake friction plates, washers and various joints, Accessories and trims, etc. The motors, rectifiers and control, braking, electrical and signal systems on railway trains also rely on copper and copper alloys to work. In addition, the electrification of railways requires a large amount of copper and copper alloys.in the aircraft Copper for wiring, hydraulic, cooling and pneumatic systems, aluminum bronze tubing for bearing retainers and landing gear bearings, and diamagnetic copper alloy for navigation instruments. |

|

Mechanical and Metallurgical Industries: |

In addition to a large number of copper used in motors, circuits, hydraulic systems, pneumatic systems and control systems in mechanical engineering, various transmission parts and fixing parts, such as cylinder liners, connectors, fasteners, gears, twisting parts, etc., all Need to reduce wear and lubrication with copper or copper alloy. The key component in continuous casting technology of metallurgical equipment-crystallizer, mostly made of high strength and high thermal conductivity copper alloy such as chromium copper, silver copper, etc., and the vacuum arc furnace and electroslag furnace water-cooled crucible in electrometallurgy are made of copper pipe, and various induction heating The induction coils are all made of copper tubes or special-shaped copper tubes, which are cooled by water. |

|

light industry: |

|

|

Emerging industries and high-tech fields: |

|

Product Parameters

| Type | Copper coil tube | |

| Standard | GB/T17791-2007,GB/T1527-2006, GB/T18033-2007, YS/T450-2002 | |

| ASTM B280,ASTM B68,ASTM B75,ASTM B88 | ||

| EN12735,AS1571,JIS H3300,etc. | ||

| Wall Thickness | 0.3mm~80mm,Or As Customization | |

| Outside Diameter | 2mm~610mm,Or As Customization | |

| Material | C1220,C12000,C10200,T1,T2,T3,TP2,TU1,TU2,TU etc | |

| Temper condition | soft (M), half soft (M2) and half hard (Y2) | |

| Processing Service | Bending, Decoiling, Welding, Punching, Cutting.mill,polished,bright,oiled,hair line,brush,mirror,sand blast,or as required. | |

| Application | Water tube, Air condition or Refrigerator, Water heater | |

| Pipe shape | Round, square, rectangular,etc | |

| Application | Water tube, Air condition or Refrigerator, Water heater , etc | |

| Delivery Time | within 7 days,according to the quantity ordered by the custome |

Product Specifications

|

specifications |

Wall thickness (mm) |

Length (m) |

|

Φ6 |

0.5 |

15 |

|

Φ7 |

0.6 |

15 |

|

Φ7.94 |

0.6 |

15 |

|

Φ9.52 |

0.6 |

15 |

|

Φ12.7 |

0.7 |

15 |

|

Φ15.88 |

0.9 |

15 |

|

Φ19.05 |

1.0 |

15 |

|

Φ22.23 |

1.0 |

15 |

| Product Details | Product Production | Product Warehouse |

|

|

|

|

|

|

Applications

Copper tube coils are widely used in air conditioning systems, water supply systems, fire protection, fluid transportation, power systems, transportation manufacturing, industrial manufacturing, parts processing and other fields.

Project Cases

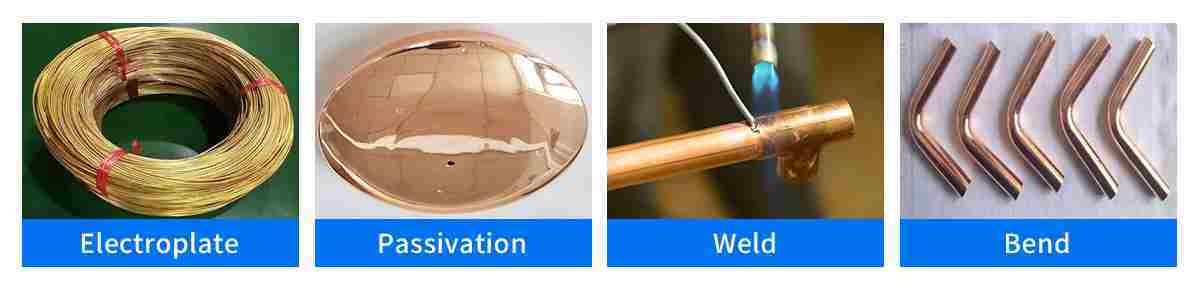

Additional Processing Technology

We can provide additional processing techniques for copper tube coils, such as passivation treatment, electroplating; Cutting,bending, welding, marking, etc.

Product Packaging

Product Transportation

FAQ

How to contact us?

If you are interested in our products, please feel free to contact us at any time. You can contact our product manager through email or the message board at the bottom of the page.

What are your main products?

Our main products are stainless steel products, galvanized steel products, aluminum profiles and lead products. In addition, we also have steel pipes, steel plates and other related steel products.

Do you provide customized product services?

Of course, our professional R&D team can design and produce the products you need according to your specifications and drawings. For example: special size, special control, OEM, etc.

How long will it take for me to get the price?

Please provide product specifications such as material, size, quantity and other requirements. We usually quote within 6 hours, and steel prices fluctuate with the market every day. Our prices are very competitive because we have a stable supply chain. If you would like to get a price as soon as possible, please call us or let us know by email so that we can prioritize your inquiry.

Are you a manufacturer?

Our main products are stainless steel products and galvanized steel products. Our own factory, coupled with our many years of experience in the domestic steel market and long-term cooperation with upstream and downstream suppliers, stable prices, stable quality and stable supply capabilities allow us to have great advantages in stainless steel and galvanized products. At the same time we also have product resources of carbon steel products and color-coated coils, I believe this will also make you satisfied.

Can we visit your factory?

Of course, we welcome you to visit our factory on site or visit our production line through online video to understand our strength and quality. We will arrange a professional team to serve you.You just need to send your itinerary and leave the rest to us.

What say our customers

Keywords

C11000/T2 Copper Coil

Contact Us

Classification