Categories

Aluminum

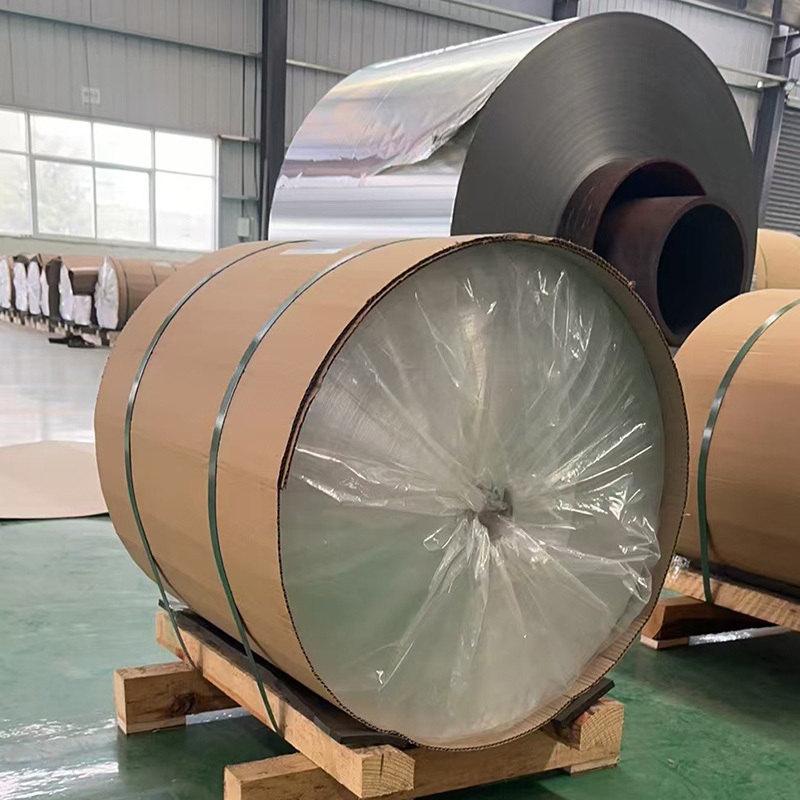

1050 aluminum alloy is formed by adding a small amount of copper in pure aluminum, which has excellent forming characteristics, high corrosion resistance, good weldability and electrical conductivity. It is widely used in products with low strength requirements, such as chemical instruments, sheet metal processing parts, deep drawing or spinning concave vessels, welding parts, heat exchangers, clock surface and disk surface, nameplate, kitchen utensils, decorations, reflective appliances, etc.

1050 aluminum alloy is formed by adding a small amount of copper in pure aluminum, which has excellent forming characteristics, high corrosion resistance, good weldability and electrical conductivity. It is widely used in products with low strength requirements, such as chemical instruments, sheet metal processing parts, deep drawing or spinning concave vessels, welding parts, heat exchangers, clock surface and disk surface, nameplate, kitchen utensils, decorations, reflective appliances, etc.

1050 aluminum alloy is formed by adding a small amount of copper in pure aluminum, which has excellent forming characteristics, high corrosion resistance, good weldability and electrical conductivity. It is widely used in products with low strength requirements, such as chemical instruments, sheet metal processing parts, deep drawing or spinning concave vessels, welding parts, heat exchangers, clock surface and disk surface, nameplate, kitchen utensils, decorations, reflective appliances, etc.

1050 aluminum alloy is formed by adding a small amount of copper in pure aluminum, which has excellent forming characteristics, high corrosion resistance, good weldability and electrical conductivity. It is widely used in products with low strength requirements, such as chemical instruments, sheet metal processing parts, deep drawing or spinning concave vessels, welding parts, heat exchangers, clock surface and disk surface, nameplate, kitchen utensils, decorations, reflective appliances, etc.

1050 aluminum alloy is formed by adding a small amount of copper in pure aluminum, which has excellent forming characteristics, high corrosion resistance, good weldability and electrical conductivity. It is widely used in products with low strength requirements, such as chemical instruments, sheet metal processing parts, deep drawing or spinning concave vessels, welding parts, heat exchangers, clock surface and disk surface, nameplate, kitchen utensils, decorations, reflective appliances, etc.

3A21 aluminum alloy is an ordinary industrial pure aluminum with an aluminum content of 99.0. It can not be strengthened by heat treatment; the strength is low, but it has good ductility, formability, weldability and corrosion resistance; after anodic oxidation, it can further improve its corrosion resistance and obtain a beautiful surface.

The 1100 aluminum alloy is an ordinary industrial pure aluminum with an aluminum content of 99.0. It can not be strengthened by heat treatment; the strength is low, but it has good ductility, formability, weldability and corrosion resistance; after anodic oxidation, it can further improve its corrosion resistance and obtain a beautiful surface.

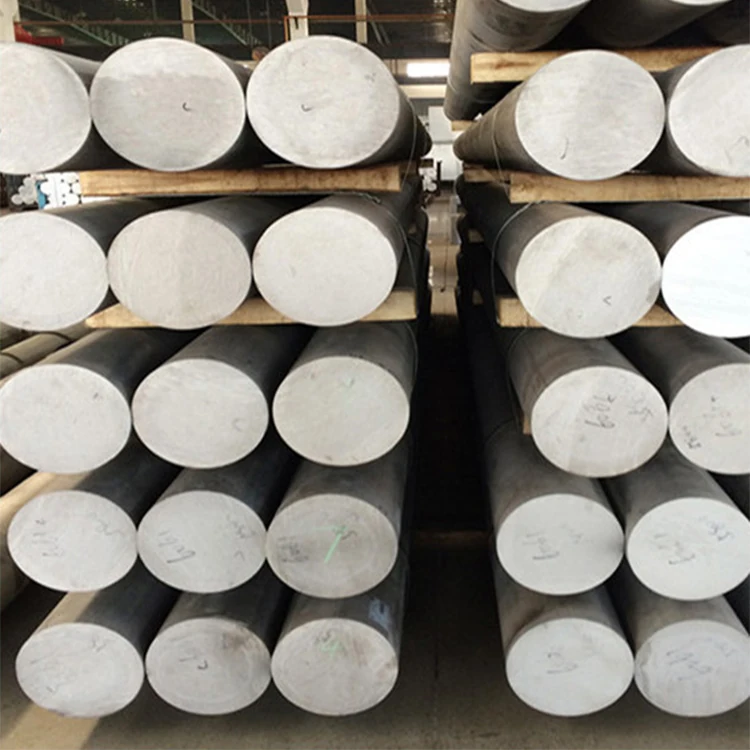

Aluminum profile is a structural material made of aluminum alloy as the main raw material. It is the most widely used non-ferrous metal structural material in industry. Aluminum profiles have many advantages, such as high strength, light weight, good corrosion resistance, electrical and thermal conductivity. They are usually made through processes such as extrusion molding, and come in a variety of cross-sectional shapes, including solid, hollow and composite types.

Aluminum profile is a structural material made of aluminum alloy as the main raw material. It is the most widely used non-ferrous metal structural material in industry. Aluminum profiles have many advantages, such as high strength, light weight, good corrosion resistance, electrical and thermal conductivity. They are usually made through processes such as extrusion molding, and come in a variety of cross-sectional shapes, including solid, hollow and composite types.

Aluminum profile is a structural material made of aluminum alloy as the main raw material. It is the most widely used non-ferrous metal structural material in industry. Aluminum profiles have many advantages, such as high strength, light weight, good corrosion resistance, electrical and thermal conductivity. They are usually made through processes such as extrusion molding, and come in a variety of cross-sectional shapes, including solid, hollow and composite types.

Aluminum profile is a structural material made of aluminum alloy as the main raw material. It is the most widely used non-ferrous metal structural material in industry. Aluminum profiles have many advantages, such as high strength, light weight, good corrosion resistance, electrical and thermal conductivity. They are usually made through processes such as extrusion molding, and come in a variety of cross-sectional shapes, including solid, hollow and composite types.

Aluminum profile is a structural material made of aluminum alloy as the main raw material. It is the most widely used non-ferrous metal structural material in industry. Aluminum profiles have many advantages, such as high strength, light weight, good corrosion resistance, electrical and thermal conductivity. They are usually made through processes such as extrusion molding, and come in a variety of cross-sectional shapes, including solid, hollow and composite types.